Solar panels on some hidden crack is not obvious, also can't see the naked eye, a lot of people will feel that there is not much problem, can continue to use, actually otherwise, cracked causes factor is directly cause the loss of the solar panel power, there may be some very slight, current test power won't have too big change, but after a few months, a year of heat bilges cold shrink, The power of the solar panels will drop dramatically. Even some serious internal short circuit will cause fire and so on.

So how do these cracks happen? There are many reasons for solar panel cracking in the production process, and there are three fundamental reasons:

Raw material defect: purchased inferior materials or improper placement of solar cells and mc4 solar cables to this cabinet, resulting in the problem of hidden cracks in the battery itself

Mechanical factors: This is mainly in the process of welding (machine series welding), the battery due to improper temperature parameters set by the machine, resulting in expansion at high temperature and hidden crack, there is a machine failure.

Human factors: When the customer is welding positive and negative poles, as well as stacking, the manipulation of the battery sheet is not correct, which may not be visible to the naked eye at that time, thinking that there is nothing wrong.

So how do you detect cracks in solar panels?

So how do you detect cracks in solar panels?

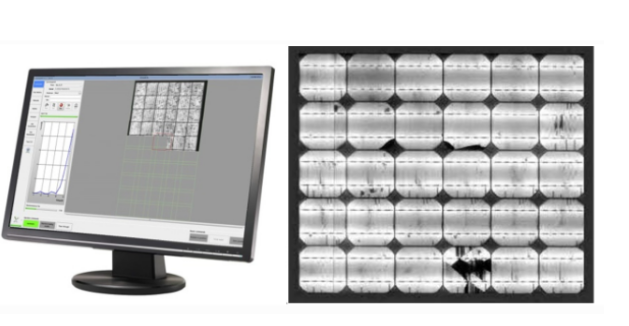

EL devices

An Electroluminescence (EL) device is a kind of solar cell or module internal defect detection device. It uses the electroluminescence principle of crystalline silicon to capture near-infrared images of the components with a high-resolution infrared camera. This device can obtain and determine defects in components. Generally, after the solar cells arrive at the warehouse, the source screening is carried out by the sorting room to screen out the defects of raw materials. Secondly, after welding the positive and negative electrodes, they are put on the EL test bench to avoid hidden cracks caused by improper operation of employees.

2. IV equipment

The IV device can identify various solar panel failures through curves displayed on the computer. With fast reaction time. The test takes just five minutes to complete. It is generally used after the product is laminated.

So how do we avoid solar panel cracks?

To the staff training, let the staff pay attention to the operation methods.

Avoid falling during transportation

Avoid machine setup errors

.